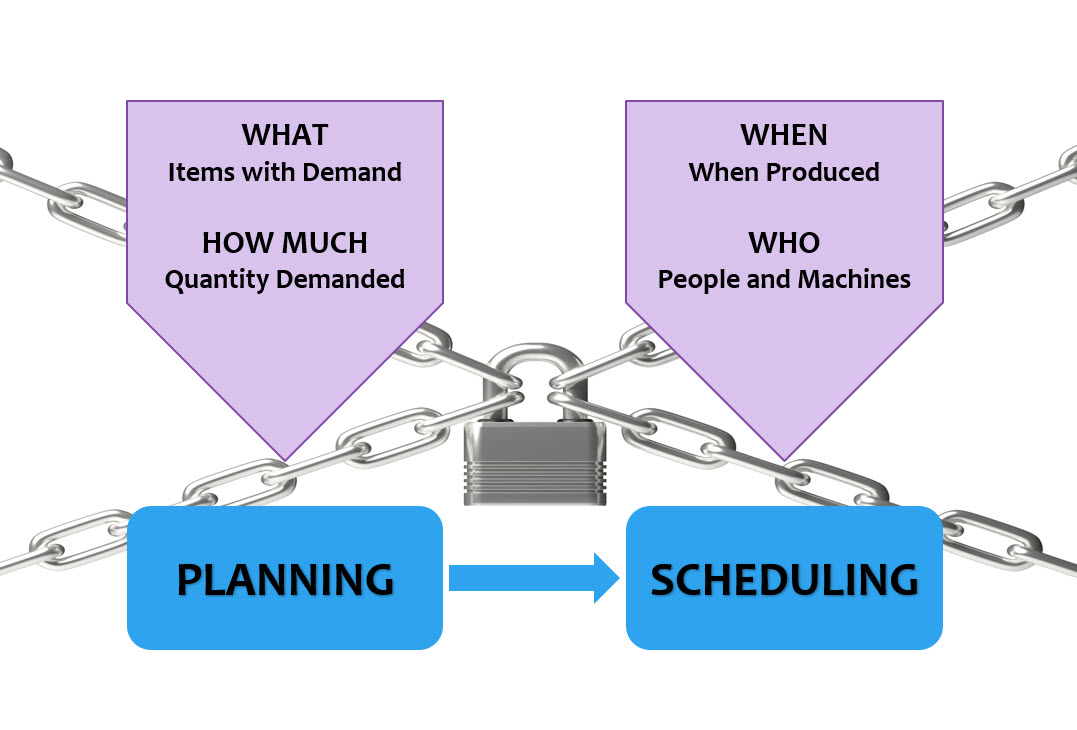

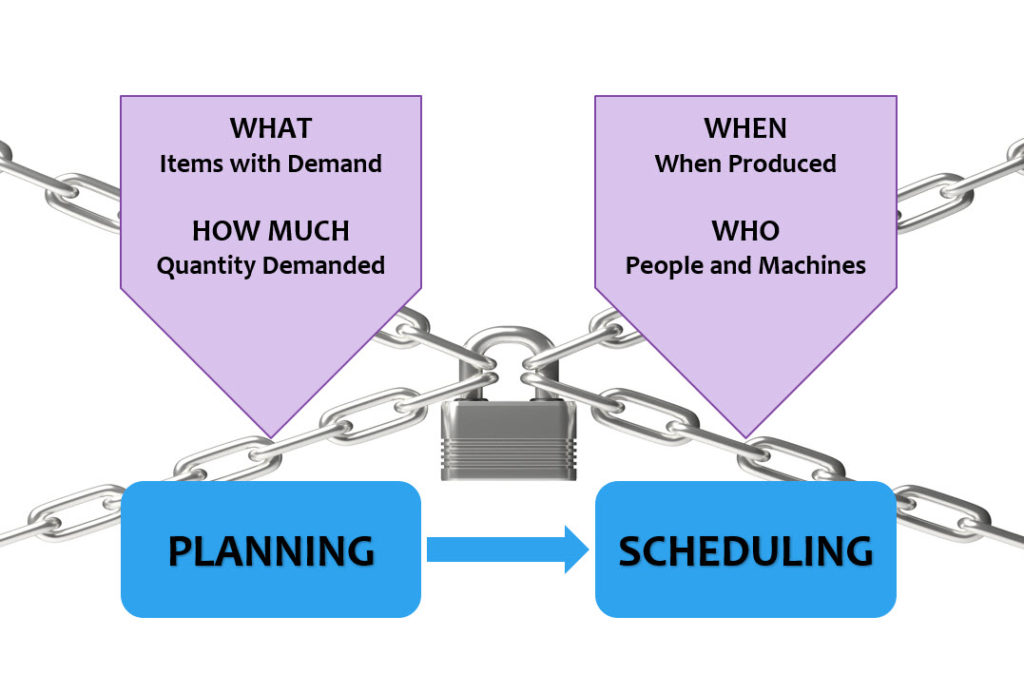

While the Planning and Scheduling are two activities that are commonly referred to as the same task, there is an important distinction between them. It is important to define this distinction because manufacturing constraints affect scheduling and not planning.

Planning is the process of identifying how much of an item that needs produced. Planning does not care whether it is possible to produce a certain quantity. It only answers the question of how much of an item is demanded by my customers based on actual customer demand and forecasted customer demand. The result of this process is a Plan, commonly known as a Master Production Schedule. The Plan only identifies “What” and “How Much”.

Scheduling is focused on identifying when the Plan can be executed. Here is where constraints come into play. The Plan identifies every item that has demand and the quantity required of each time. The Schedule takes into consideration resource capacity, time, and other constraints or attributes that are used to determine when the items can be manufactured.

Most ERP systems have planning and scheduling modules, and typically an ERP system performs calculations assuming that capacity is infinite. This is perfectly acceptable for Planning. When Planning, we want to know the total quantity required of an item. We don’t care in the planning process whether it is possible to make that quantity—that is Scheduling’s job. Here is where ERP systems typically fail. When Scheduling, we need to apply the constraints of our manufacturing process to the Plan. Because ERP systems are infinite, it will be near impossible to calculate a manufacturing schedule with accurate estimated manufacturing dates without applying capacity constraints. An APS system is designed to work with your ERP’s Plan and apply finite capacity constraints to develop a feasible production schedule.

By defining the differences between Planning and Scheduling, we can then become better at developing plans unconstrained and then developing schedules applying our constraints to understand the demand vs what’s possible.

ABOUT US

Scheduling Solutions is uniquely positioned to bring you the finest APS technology with the most experienced APS implementation team in North America.

Most manufacturers recognize that, in order to compete in today’s fast-changing world, they need an APS solution that addresses their unique needs. They also recognize that most APS solutions on the market do not work, cannot work, and will never work.

APS is all we do, and our team can proudly claim that we have implemented successful APS solutions in over 150 manufacturing sites in North America.

CONTACT US

Head Office – 5454 Lena Road, Suite 105 Bradenton, FL 34211, USA

Phone: 941-259-4434

Email: info@lsi-scheduling.com

Website: https://www.lsi-scheduling.com/